47+ Warehouse Statistics: Industry, Automation, & More For 2025

The warehouse industry is critical to global supply chains and supports businesses and economies. But just how much do we know about its latest trends?

With that in mind, I’ll cover essential warehouse industry statistics that reveal its growth and future prospects.

Warehouse Statistics: Key Numbers

- The global warehousing market was $1.01 trillion in 2023 and is expected to grow 8.1% from 2024 to 2030.

- As of 2023, the U.S. has over 21,000 warehouses, up from 14,600 in 2007.

- Personnel costs make up 56.7% of the overall warehouse cost structure.

- US warehousing and storage was $86.1 billion in 2023 and expected to reach $107. billion by 2032, growing 2.4%.

Source: (Warehousing and Fulfillment, Leeline Sourcing, Grand View Research)

Warehouse Automation Statistics

- The warehouse automation market was $23.44 billion in 2023 and is expected to grow to $41.00 billion by 2027.

- The warehouse automation market is expected to grow by 75% between 2023 and 2027.

- 65% of automation considerations are driven by labor shortages, supply chain disruptions, and the rise in eCommerce.

- Automation in warehousing cuts labor costs by 60%.

- Warehouse automation reduces operational errors by 99%.

- Automation boosts warehouse storage capacity by 50%.

- 41% of companies face budget constraints, 40% are concerned about ROI, and 37% struggle with training during automation adoption.

Source: (Statista, Modern Materials Handling, Vecna Robotics)

Top Considerations for Warehousing Automation Solutions

Multiple factors influence the adoption of warehouse automation solutions across the industry. Let’s explore the main drivers behind this shift:

- 25% of automation considerations are driven by labor shortages.

- 22% of automation considerations are due to supply chain disruptions.

- 18% of automation decisions are influenced by the rise in eCommerce and direct-to-consumer models.

- 15% of automation solutions are driven by reshoring manufacturing.

- 12% of automation initiatives are prompted by corporate directives.

- 8% of automation considerations are due to throughput problems.

Source: Vecna Robotics

Global Warehouse Market Size

The warehouse market size is set to grow substantially due to increased product demand. Below is an overview of key trends behind this expansion:

| Year | Warehouse Market Size (in trillion dollars) |

|---|---|

| 2023 | $1.0 |

| 2024* | $1.08 |

| 2025* | $1.17 |

| 2026* | $1.26 |

| 20278 | $1.37 |

| 2028* | $1.48 |

| 2029* | $1.6 |

| 2030* | $1.72 |

Source: Statista

Warehouse Management System Usage (2015-2021)

Between 2015 and 2021, companies consistently utilized warehouse management systems at high rates despite some yearly changes. Below are the yearly usage details:

| Year | Usage of WMS (%) |

|---|---|

| 2015 | 85% |

| 2016 | 83% |

| 2017 | 87% |

| 2018 | 93% |

| 2019 | 85% |

| 2020 | 85% |

| 2021 | 83% |

Source: Statista

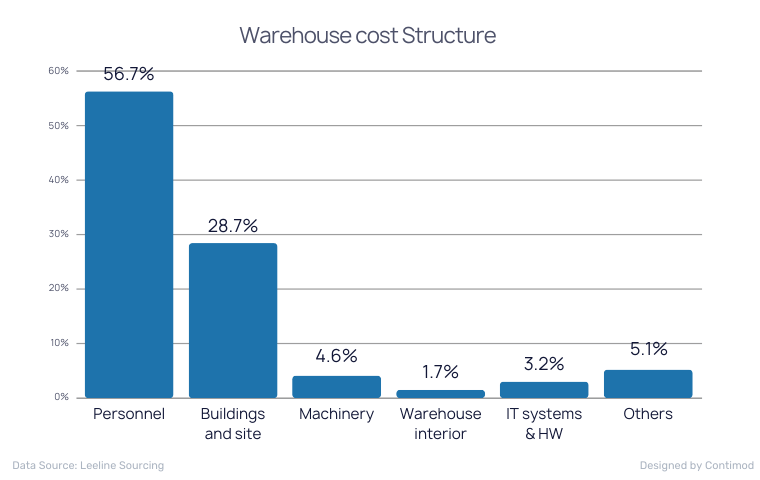

Warehousing Cost Breakdown

Warehousing cost distribution covers several essential components. Below is an outline of these components:

- Personnel: 56.7%

- Buildings/Site: 28.7%

- Machinery: 5.1%

- Interior: 4.6%

- IT/Hardware: 3.2%

- Others: 1.7%

Source: Leeline Sourcing

Major issues in Warehouse Operations

Warehouse operations face multiple challenges like workforce shortages, space limitations, and outdated equipment. The primary challenges in operations are:

- 59% of warehouses/DCs struggled to attract and retain a qualified hourly workforce.

- 36% of facilities faced insufficient space for inventory or required modifications.

- 36% reported challenges in attracting and retaining qualified supervision.

- 36% experienced issues with outdated storage, picking, or material handling equipment.

- 21% had inadequate information system support.

- 15% lacked SKU weight and dimension information in their system.

- 23% dealt with an obsolete layout for current requirements.

- 8% faced a lack of higher management support.

- 33% were challenged by the surge in e-commerce volume.

Source: Peerless Research Group (PRG)

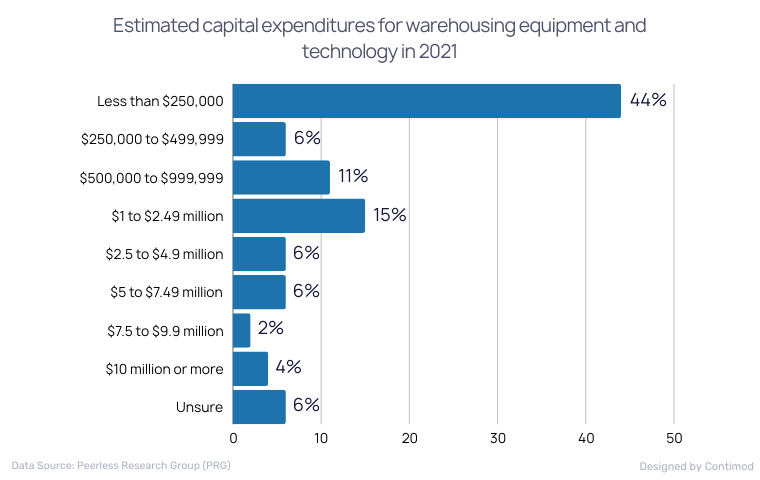

Warehousing Equipment & Technology Spending

A wide range of budgets are used by businesses to invest in warehousing technology and equipment. According to Peerless Research Group (PRG), these costs are being split up like this in 2021:

- 44% spent less than $250,000.

- 6% spent between $250,000 and $499,999.

- 11% spent between $500,000 and $999,999.

- 15% spent between $1 million and $2.49 million.

- 6% spent between $2.5 million and $4.9 million.

- 6% spent between $5 million and $7.49 million.

- 2% spent between $7.5 million and $9.9 million.

- 4% spent $10 million or more.

- 6% were unsure about their spending.

Source: Peerless Research Group (PRG)

To learn more about warehouse technology, we recommend visiting our warehouse automation statistics resource page to get a clear understanding of warehouse automation trends.

Materials Handling Systems in Use

Materials handling systems are integral to operations today and their adoption spans a range of technologies. Here is an overview of the systems currently in use:

| Material Handling System | (%) in Use |

|---|---|

| Forklifts | 83% |

| Push Carts | 55% |

| Conveyors | 37% |

| Vertical Lift Modules | 25% |

| Palletizer | 19% |

| Robotics/Articulating Arms | 12% |

| Sorters | 12% |

| AGVs/AMRs | 9% |

| Carousels | 9% |

| Other | 6% |

Source: Peerless Research Group (PRG)

The Most Congested Area in Warehouses

Warehouse congestion varies across different areas which affects efficiency and productivity. Here is a look at congestion levels in key warehouse zones:

| Area | Percentage (%) |

|---|---|

| Storage area | 29% |

| Receiving dock | 24% |

| Shipping dock | 21% |

| Pack area | 9% |

| Pick area | 7% |

| E-commerce processing | 4% |

| Value services processing | 4% |

Source: Peerless Research Group (PRG)

If you owned or operated a warehouse, then it is essential to store the product and merchandise using storage container solutions. And if you need help finding the conex box, then Contimod can help you find a container supplier that serves your area.